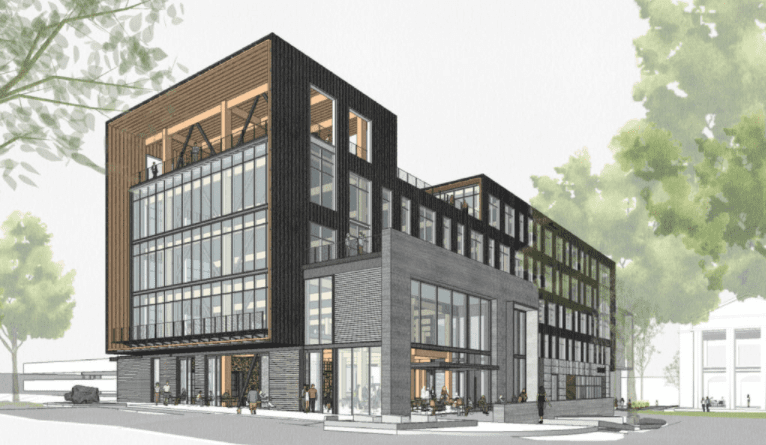

STRUCTURAL ENGINEERING AND DESIGN

Our in-house design and structural engineering department brings industry experience of over 25 years to your building project, with some of the leaders in the start of the mass timber industry in the US. Our team participates in the development of national CLT manufacturing and design standards and are knowledgeable of mass timber building code acceptance and innovative design solutions developed in academia and for specific projects around the world. We can work directly with the engineer of record to provide design guidance and help educate the next generation of industry professionals or can partner with a local engineering firm licensed in 50 US states and 7 Canadian provinces to complete the design internally.

SmartLam’s interdisciplinary staff of designers, structural engineers, industry professionals and manufacturing experts are dedicated to optimizing a solution for every project. Bringing our team on-board as a design-assist partner early in the design process to work directly with the owner, architect, engineers and construction team will ensure reduced project delivery times.

As a manufacturer of CLT, we are often able to provide the missing link for project teams who are not familiar with the manufacturing process or typical detailing requirements. Through close coordination, SmartLam has been involved in projects that have achieved success through shorter design schedules, value engineering, reduced construction schedules and better performing structures overall. Thanks to these previous successes, we’re able to provide numerous design-assist services for your current or future projects.

Our drafting and modeling experts can provide the following advantages for your current and future mass timber projects:

• Advanced Cadwork modeling including CLT, glulam, steel and auxiliary building elements

• Direct shop drawing output for CLT, GL and steel

• Export/import IFC files that will interface with most 3D software programs (AutoCAD, Revit, Rhino, and others)

• Optimize CLT panel nesting

• Direct digital output to CNC machine

• Precise connection interfaces for accurate detailing

• Coordination and modeling of trade openings including mechanical, electrical and pluming

• Material and fastener take-offs for sourcing and procurement

• Virtual walk throughs

• Clash detection

• Define assembly order and automate installation

• Identify center of gravity of panels for pick points and lifting on-site

Featured Services:

• Building code analysis and interpretation

• Schematic and preliminary design of steel and mass timber structural framing systems to optimize layout plans and reduce member sizes

• Design development

• Custom glulam design including tapered and arched

• Peer design review

• Constructability review to maximize prefabrication opportunities and reduce installation time

• Deferred submittal engineering

• Value engineering

• Mass timber connection systems

• Mass timber composite design

• CLT floor vibration

• Mass timber fire design

• Nonlinear finite element analysis

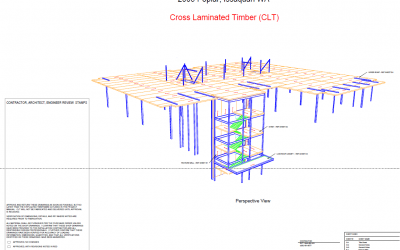

• Desk studies and testing of innovative mass timber systems SmartLam NA runs a Design for Manufacturing and Assembly (DfMA) process. One mass timber advantage over other types of structures is the ability to prefabricate – saving time and money on the job site, installation efficiency is maximized and costly mistakes can be avoided. After working closely with your design team to reach an effective building solution and prepare construction documents, SmartLam models every structure using an industry wide 3D modeling software.

Beyond SmartLam CLT, wood and steel beams, connectors and fasteners can all be included in the model, allowing our experienced designers to identify potential installation issues, optimize fabrication and reduce labor on-site. From our precise 3D model, we generate shop drawings and send cutting paths directly to our CNC machines for final processing. While this process often takes longer than the actual production time, it is important that the construction team plans for this design and coordination in advance which will ultimately save time and headaches on the job site during installation.

Our Process

Our dedicated team provides full-suite project management. Whether you’re new to mass timber or an industry veteran, our dedicated team provides end-to-end project management services to ensure your project is a success.

Project Design

From conceptual design through final construction documents, our project management and design professionals are available to meet all your needs including, product application support, budgetary guidance, design assist services, onsite logistics planning and more.

Shop Drawings and Pre-Production Planning

Once your project is contracted the mass timber design and shop drawing phase begins. Your project manager will work through important downstream considerations with you including freight, onsite spatial constraints, installation sequencing and more as part of this process to ensure the design is perfectly suited to your needs. A suite of state-of-the-art 2D and 3D deliverables will then be made available for approval and coordination with other trades. Upon shop drawing approval, a production schedule is then confirmed.

Manufacturing

The manufacturing process is carefully executed according to the project erection schedule and installation sequencing established earlier. Your project manager will keep you informed of progress through the process. Design and installation sequence changes at this phase are possible but highly discouraged as they incur additional costs and can disrupt or reset the schedule.

Installation

As your installation date nears, your project manager will work with you to confirm truck loadouts, and delivery dates and times. We are also available to review installation details and best practices with your site Superintendent and installers. Products are delivered carefully wrapped and clearly labeled to ensure a smooth process on the receiving end. Supplemental material information lists with weights and dimensions, individual piece shop drawings, and easy to navigate 3D visualizations are also available to help your install teams.

Technical Support

Throughout all phases of your project, our project managers, designers and engineers are available to help every step of the way. Our mission is to help you deliver projects on time and budget, through a seamless experience that leaves you excited to embark on your next mass timber project.