Over the past 10 years, there has been a growing interest in tall buildings constructed from mass timber materials with dozens of timber buildings above eight stories tall being constructed around the world. In January 2019, the International Code Council (ICC) approved a set of proposals to allow tall wood buildings as part of the 2021 International Building Code (IBC). The new code allows for the use of mass timber materials for up to 18 stories for business and residential buildings. SmartLam NA Cross Laminated Timber (CLT) is industry certified and is a product of choice for mass timber construction.

ABOUT CLT

Cross Laminated Timber is the next generation of building products. Extensively tested and widely used in Europe for the past 20 years, CLT can be used for many applications such as construction, industrial matting, bridging and beyond. Because of CLT’s amazing strength, rigidity and stability, it is a cost-competitive replacement for the traditional structural materials like steel, concrete, and masonry.

Manufacturing CLT

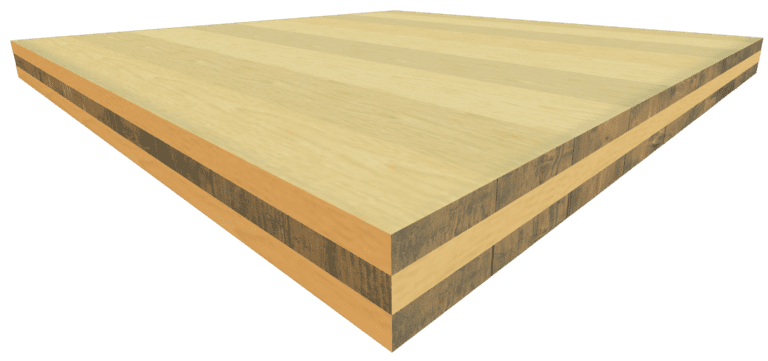

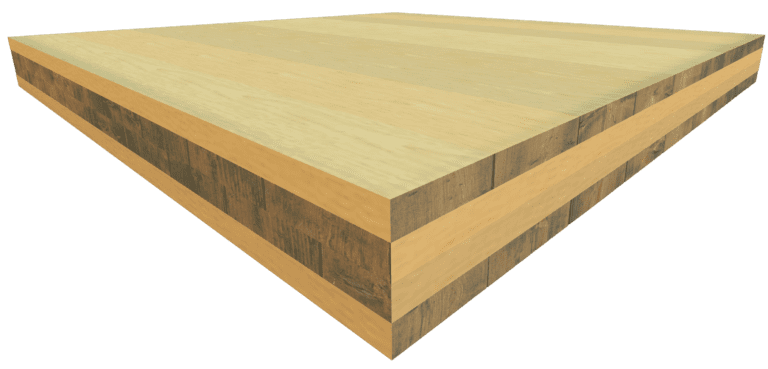

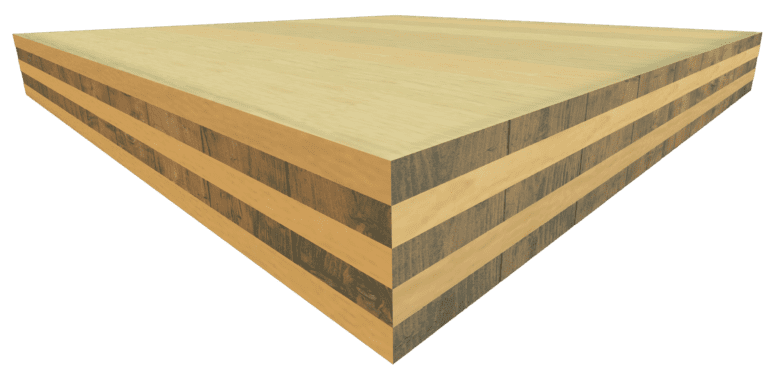

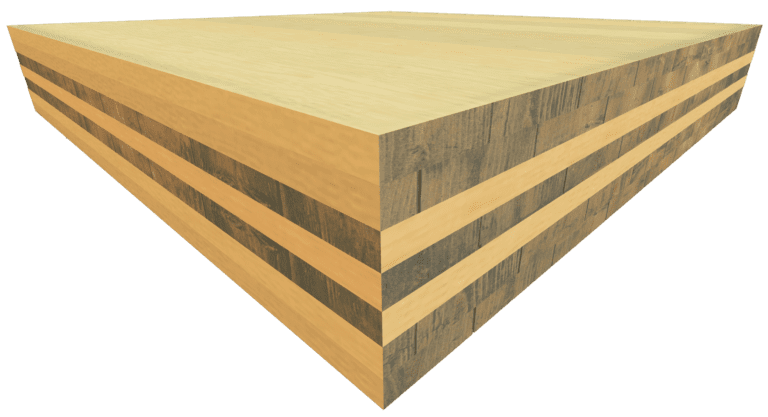

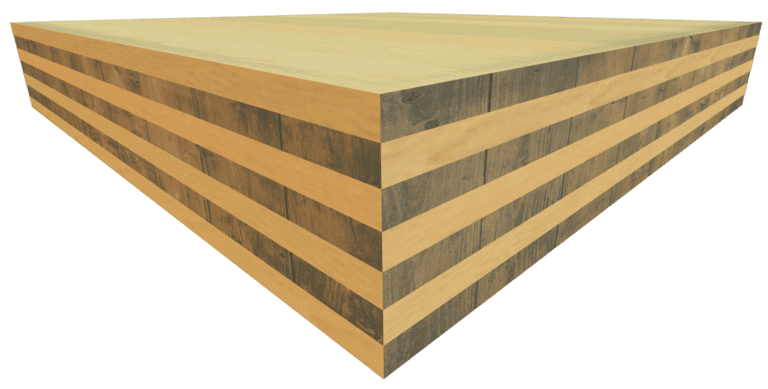

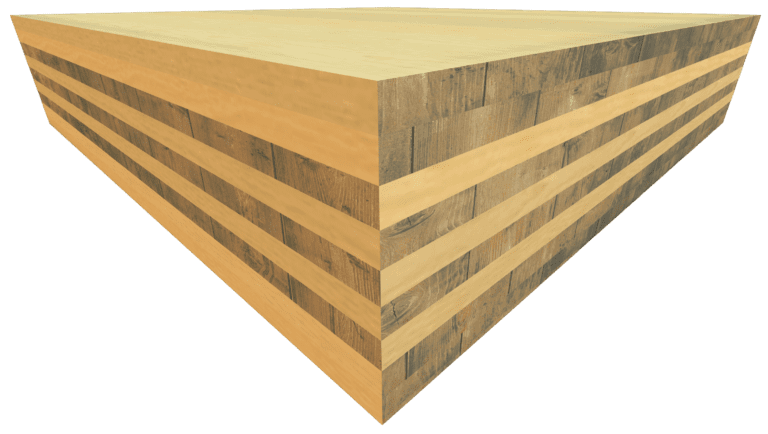

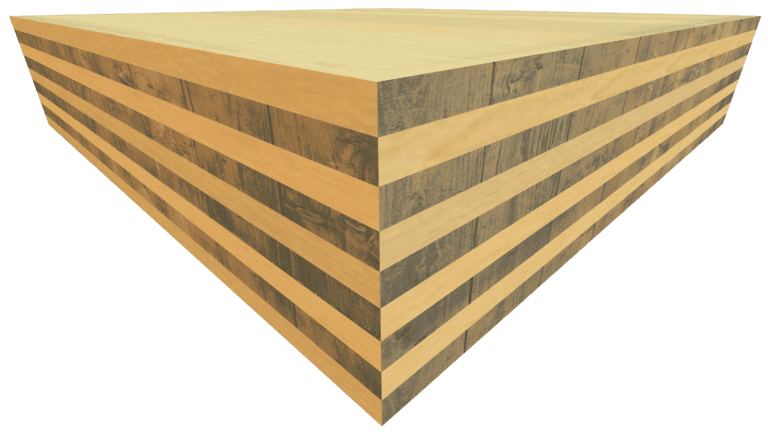

A Cross Laminated Timber panel consists of several layers of kiln-dried lumber boards stacked in alternating directions, bonded with structural adhesives, and pressed to form a solid, straight, rectangular panel. CLT panels typically consist of an odd number of layers (usually, three to seven or more). This cross lamination provides dimensional stability, strength and rigidity, making CLT a viable alternative to conventional framing, concrete, masonry and steel in many applications. It can be used for an entire building, as both the lateral and vertical load resisting system, or for select elements such as the roof, floors or walls. CLT as a structural panel element is also used as a superior bridging and retaining wall product that replaces heavy timbers, steel, and concrete.

SmartLam NA uses Douglas-Fir, Western Larch, Engelman Spruce, Sitka Spruce, White Spruce, Lodgepole Pine, Western Hemlock, Nobel Fir, Red Fir, Grand Fir, Silver Fir, White Fir, Douglas Fir, Western Larch, Shortleaf Pine, Longleaf Pine, Slash Pine, Loblolly Pine & SPF Grade 2 and Better.

The boards are kiln dried to a moisture content of 12% +/- 3%. Proper moisture content provides for proper adhesion and prevents dimensional variations and surface cracking.

According to the strength and final visual quality, defects such as large knots and resin or bark pockets are removed.

The boards are trimmed and finger-jointed to obtain the desired lengths and quality of lumber. SmartLam can produce solid wood panels up to 41’ long. Our new plant will be capable of producing panels 12′ wide and 64′ long.

Panels are assembled by placing the finger-jointed boards side-by-side (to achieve the desired length & width) to form solid wood layers. Each succeeding layer is laid perpendicular to the preceding layer.

HISTORY OF CLT

Cross-laminated timber was developed in Austria in the early 1990s. It has been popular in Europe for more than 20 years, with extensive research and a documented track record supporting its widespread use.

In the early 2000’s construction with CLT increased dramatically in Europe, driven by the green building movement as well as code changes and improved marketing and distribution channels. There are hundreds of impressive buildings built around the world using CLT that show the many advantages this product can offer to the construction sector. In North America, CLT is relatively new but is quickly gaining momentum. SmartLam was the first Cross Laminated Timber manufacturer in the United States.

The need to provide a lighter, low carbon, renewable and sustainable building material to architects, engineers, developers and contractors is driving the demand for architectural CLT in North America. The American National Standards Association has approved the ANSI/APA PRG 320-2012 Standard for Performance-Rated Cross-Laminated Timber, a product standard that details manufacturing and performance requirements for qualification and quality assurance. CLT was also recently included in the 2015 International Building Code (IBC). Up until now and in areas that have not yet adopted the 2015 IBC, several innovative architects and designers have already specified and built CLT structures in the U.S. and Canada, having had them approved under their local building code as an alternative building system.

BENEFITS & ADVANTAGES OF CLT

SmartLam CLT is manufactured from trees harvested in sustainably managed forests. The raw materials for SmartLam CLT are sourced exclusively from small and medium diameter timber. This responsible cultivation practice maintains and even enhances the long-term productivity and health of the forest. CLT provides several environmental benefits in addition to its excellent thermal performance. Wood is the only major building material that grows naturally and is renewable. CLT also has a lighter carbon footprint as wood products continue to store carbon absorbed by the trees while growing, and engineered wood manufacturing requires significantly less energy to produce than concrete and steel. This represents a significant reduction in greenhouse gas emissions.

CLT panels form a robust, structurally strong building system that outperforms anything currently available in the USA. Cross lamination provides for superior dimensional stability and offers significant shear strength performance at a unique weight to strength ratio compared to other common structural materials.

The cost of CLT versus certain concrete, masonry and steel building types and including the advantages of faster construction time and lower foundation costs.

The only constituents of a CLT building system are wood and

a non-toxic/non-VOC adhesive. CLT building materials do not introduce any toxins into the indoor environment providing clean indoor air quality.

From one-person builders to large construction companies, CLT building projects consistently report overall shorter build times requiring less personnel.

CLT’s thick cross-section provides valuable and superior fire resistance. Due to its mass, CLT panels char slowly. Once charred, combustion slows and eventually stops.

Due to the extraordinary combination of faster build, significantly reduced truck traffic, smaller work crews, quieter erection methods, and reduced on-site waste.

With proper design and maintenance, wood structures can provide long and useful service lives equivalent to other building materials. The key is careful planning and understanding of environmental loads and other external factors.

CLT panels are manufactured for specific end-use applications, which results in little to no job site waste. SmartLam is a “zero waste” facility and utilizes all residuals either through

re-purposing, as wood product constituents, or biofuel.

Because of their dimensional stability and rigidity, CLT panels create an effective lateral load resisting system. In Japan, for example, a seven-story CLT building was tested on the world’s largest shake table. It survived 14 consecutive seismic events with almost no damage.

Wood is naturally hygroscopic and inherently serves as a moisture management system within a building envelope. Wood’s inherent ability to absorb and emit moisture can naturally stabilize an indoor environment. CLT buildings ‘breathe’, minimizing the risk for mold growth.

The longevity of CLT components ensures that the future value of any structure remains high. CLT buildings are easily altered and remodeled and are also fully recyclable once they reach the end of their useful life.

Wood is the only major building material that grows naturally and is renewable. CLT also has a lighter carbon footprint as wood products continue to store carbon absorbed by the trees while growing, and engineered wood manufacturing requires significantly less energy to produce than concrete and steel. This represents a significant reduction in greenhouse gas emissions.

CLT has unique structural properties that allow architects and de-signers increased flexibility of design allowing for distinctive and innovative projects. Due to wood’s inherent ductility and unique strength to weight ratio, wood offers many advantages over the other common structural materials such as masonry, concrete, and steel.

CLT’s thermal performance is determined by its U-value, or coefficient of heat transfer, which relates to panel thickness. Thicker panels have lower U-values; they are better insulators and therefore require little or no insulation.